Should you invest in a packaging machine?

10 key arguments to consider before deciding to invest in packaging equipment

>>> Article taken from “Asset Packaging Machines”, Australia, with remarks related to analogy with Omniprojekt machines. Translation and editing: M. Miljković

Most manufacturing firms are aware that automating the packaging process can be beneficial, but many may be skeptical about the upfront investment. This is understandable because companies must calculate all costs, benefits and risks before deciding on a large investment. To help them in their decision, this article discusses the main advantages of packaging machines, i.e. 10 key arguments to consider before deciding to invest in packaging equipment:

Growth in market demand

At face value, demand growth is a sign that your business is doing something right. More orders means you have happy customers and you can look forward to more profits. However, as any production manager will attest, growing demand brings certain problems if the company does not have the capacity to handle it.

Additional labor costs, bottlenecks and understaffing can lead to lower profits, missed deadlines and quality problems, especially if accuracy is sacrificed for speed. If your business can’t keep up, sellers may look to your competition. In addition, the company can invest in training temporary workers, and then those workers go to competitors.

Automation can help you scale up production quickly, especially if you anticipate growth and purchase packaging machines that can be easily upgraded.

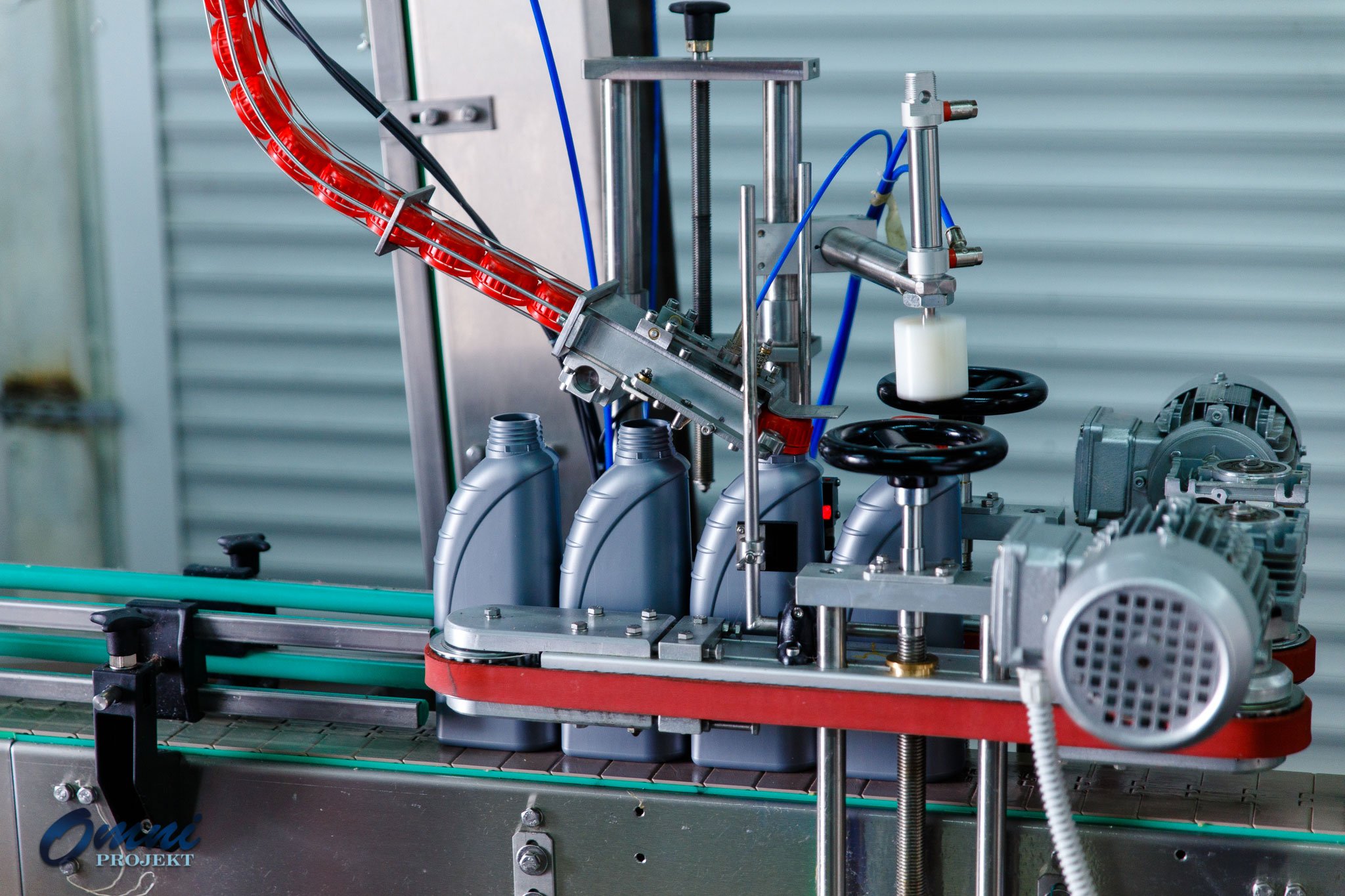

At Omniprojekt, you can buy a new or upgrade an old packaging machine to increase production volume without compromising quality. (prim. Trans.)

2. Reduction of labor costs

For most businesses, labor is expensive, especially when you factor in contributions, vacation pay, sick leave, training and retirement. Hiring more workers to increase production volume can reduce profits. What happens if a business needs to pay for overtime work or pay workers when they do work outside of the job description?

Packaging machines can also work in the mentioned cases, because the machines only need a few operators. The business does not have to worry about shifts and can redeploy staff to more productive tasks that also add value, such as customer support, management and maintenance. Overall, packaging automation reduces costs, but actually increases production and quality.

3. Reduction of scrap and discarded products

People make mistakes, which inevitably leads to extra scrap, damaged products, and the use of more material than needed to package the product. This adds up over time and can have a significant impact on profits.

Automatic packaging machines operate with high precision, reducing wasteful overfilling and underfilling, which can lead to product rejection or even legal action by inspection. Wrapping machines use fewer consumables, while automated capping machines produce fewer ill-fitting caps that can lead to leaks or spoilage. Equally important, automation also makes quality assurance much easier.

4. Improving the quality

Humans are naturally inconsistent. We overfill the containers, damage the packaging, put on the wrong labels or don’t tighten the lids enough. Because this wastes products and can upset the customer, businesses end up hiring additional quality assurance staff and trying to track down recurring errors to see if training is the problem.

Because automation produces consistent results and machine performance does not degrade due to fatigue or boredom, quality assurance becomes much easier.

5. Faster packing speed

Of course, one of the main reasons for investing in packaging machines is that they can increase capacity while reducing costs and improving efficiency. It is much easier to increase and decrease production capacity when demand fluctuates.

A packaging machine alone cannot always improve speed or efficiency, and a business may need to evaluate its entire production process. However, the experiences of successful companies prove that adding the right machine for the right process pays off very quickly.

6. Reduction of worker injuries

Packaging jobs are countless repetitions of simple movements, where operators can become mentally fatigued and lead to injuries and accidents, simply because people lose focus. In addition to morale issues, this can result in time off work, sick pay and compensation if a court finds that the company was at fault.

Automation removes workers from repetitive tasks and reduces the amount of heavy lifting, increasing productivity while reducing injuries and accidents.

7, Maintaining competitiveness

One of the realities of packaging is that more and more companies are investing in automation, especially in the Asia-Pacific region where countries like China, South Korea and Japan are making strides. Today, it is not a question of whether a company should invest in packaging technology, but “how”. Now, companies need to ask themselves how to invest, because if they don’t do it well, it could leave them uncompetitive for years to come.

Without automation, a business may be limited to lower productivity compared to the competition, and it is more difficult to respond to changing markets. Automated packaging systems don’t just give businesses an edge, they can help them survive.

8. Increasing employee satisfaction

Very few people enjoy repetitive tasks, preferring something more fulfilling. For businesses, paying the wages and expenses for these tasks can suck out profits when the same wages could support someone in a more productive role.

Automation can free workers from monotony and provide them with many jobs in sales, management, machine operation or IT. This leads to less staff turnover and more employees working in jobs they enjoy and with the opportunity for personal development.

9. Social distancing

As a result of COVID-19, businesses around the world have had to adapt to new work practices, especially supporting social distancing. Inevitably, employee spacing has significantly slowed production in a number of industries.

Since automatic packaging machines require fewer employees in the work area, maintaining social distance becomes much easier while speeding up production. With the uncertainty surrounding COVID-19, now may be a good time to look at new approaches and upgrades.

Better use of work space

Floor space costs money, and increasing production means expanding space or building new facilities, with higher business costs. If you want to increase production capacity in the same space, automated packaging systems can reduce the area of your production line.

Conclusion

These benefits have given you an insight into how packaging machines can support your business now and in the future. As part of your cost-benefit analysis, you can decide how your business can maximize the benefits of automated systems.

Automation requires planning, but involving experienced experts, such as those at Omniprojekt, can help significantly. With extensive experience in a broad portfolio of business sectors, we can help you design the right system from the start. We take into account your existing space and use a range of machines, including conveyors and accumulation tables.

Najnovije vesti

- International Fair of Packaging and Packaging Technology

Omniprojekt will participate in Warsaw Pak, the 9th trade fair for packaging and packaging technology, which will take place from 23-25 held in Warsaw, Poland in April 2024.

Omniprojekt will participate in Warsaw Pak, the 9th trade fair for packaging and packaging technology, which will take place from 23-25 held in Warsaw, Poland in April 2024. - Successfully implemented SAT in Pharmacy Zagreb

Delivered and put into operation Mixer Homogenizer 120l for semi-solid products and training of operators who will manage the machine.

Delivered and put into operation Mixer Homogenizer 120l for semi-solid products and training of operators who will manage the machine. - 30 years dedicated to perfection

From the beginning, the most important target group for us was the pharmaceutical industry, mainly because at that time there was no competition that could offer packaging equipment in the quality of Western manufacturers.

From the beginning, the most important target group for us was the pharmaceutical industry, mainly because at that time there was no competition that could offer packaging equipment in the quality of Western manufacturers. - Invest in a packer, yes or no?

10 key arguments to consider before deciding on an investment in packaging equipment, i.e. the main advantages of packaging machines

10 key arguments to consider before deciding on an investment in packaging equipment, i.e. the main advantages of packaging machines